A custom electronic project involves the full development of hardware, firmware and, when required, application software, designed specifically to meet the technical, regulatory and production requirements of an industrial product. Unlike standard solutions or generic platforms, a custom project implies custom electronics engineering from concept definition through validation and series production. Every design decision —from processor selection to PCB layout and firmware strategy— is driven by the real needs of the product and the client.

This approach is common in sectors such as industry, aerospace and defence, where performance, reliability, technological control and regulatory compliance are critical. In these environments, custom electronic design ensures product performance, scalability and intellectual property over the full product lifecycle. Companies that choose custom development are looking not only for a product that performs in demanding conditions, but also for a technical partner who understands the application domain and can evolve the design over time.

What is a custom electronic project?

A custom electronic project is an integral electronics engineering process aimed at creating a specific product for a specific client. It includes system architecture design, hardware development and preparation of the product for manufacture and certification. It is not simply a matter of integrating off-the-shelf modules: it means defining the optimal architecture —including processing, communications, power and thermal management— according to functional requirements, operating environment and expected product lifecycle.

Unlike solutions based on closed commercial products, this type of project allows the design to be fully adapted to the functional, environmental and regulatory needs of each application, ensuring greater control over the final product. The client gains a documented, reproducible design with full traceability, making it easier to carry out future revisions, certifications and production scaling without depending on a single supplier of generic boards.

What does a custom electronic project include?

A custom electronic project covers all the phases needed to take a product from the initial idea to industrial production. Below we outline the typical stages and what each contributes:

Requirements definition and architecture

This phase involves a thorough functional analysis: gathering technical requirements (performance, interfaces, power, size), regulatory ones (CE, sector-specific, military or aerospace) and lifecycle aspects (maintenance, obsolescence, second source). On this basis, the electronic and system architecture is defined: choice of processing platform (MCU, SoC, FPGA or a combination), communications strategy, power architecture and reliability and safety criteria. A solid definition at this stage reduces risk and cost in later phases.

Electronic design and PCB

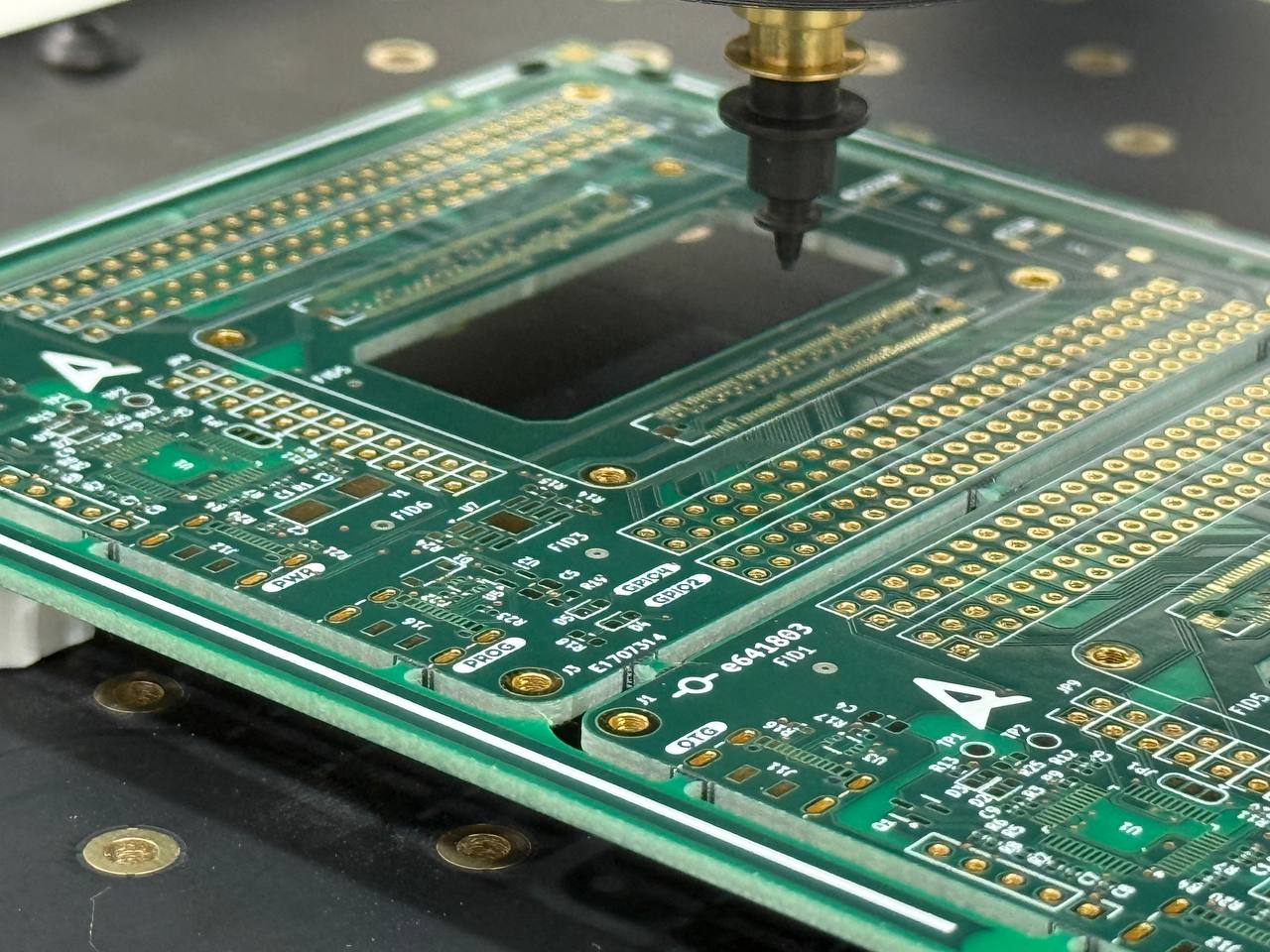

Here the architecture is realised in schematics and printed circuit board (PCB) design. It includes component selection (taking into account availability and lifecycle), design for manufacturing (DFM) to ensure the board is manufacturable and repeatable, electromagnetic compatibility (EMC) compliance and reliability criteria (temperature, vibration, lifetime). The result is a set of drawings and a manufacturing package ready for prototyping or for sending to production.

Prototyping and validation

Prototypes are manufactured and assembled according to the approved design. Functional testing then follows (behaviour versus specification), electrical validation (voltages, currents, signal integrity), thermal (operating and storage temperatures) and, where applicable, environmental (humidity, vibration, EMC). The results highlight any deviations and allow design adjustments before freezing the version for industrialisation. This phase is key to reducing risk in series production.

Industrialisation and certification

The product and documentation are prepared for series production: cost optimisation (second source for components, process simplification), definition of in-line tests and acceptance criteria, and support for certifications (CE marking, industrial, aerospace or defence standards depending on the sector). Quality control and traceability processes are also typically defined. The goal is to have a product ready for volume manufacture with the required quality and regulatory compliance.

Overall, this approach enables the development of electronic boards, embedded systems, electronic modules and communication solutions tailored to demanding industrial environments, with full traceability and design control.

When is a custom electronic project necessary?

A custom electronic project is necessary when standard solutions do not meet the product or application environment requirements. Starting from scratch is not always required: sometimes the starting point is a proprietary platform (for example a System on Module) and the application electronics are designed to measure. It is especially common to turn to custom development in the following cases:

Specific technical or regulatory requirements

When the product must comply with strict regulations (for example EMC, functional safety, aerospace or defence), severe environmental conditions (extreme temperature, humidity, vibration) or high safety requirements. Generic commercial products are rarely characterised or certified for all such environments, so a dedicated design allows compliance to be demonstrated with appropriate documentation.

Integration into complex systems

When the electronics must integrate into existing systems (industrial machinery, vehicles, communications equipment) or interact with multiple industrial subsystems. In these cases, specific interfaces, protocols and behaviours are often required that standard boards do not provide; a custom design allows the electronics to be aligned with the rest of the system from the outset.

Scalability and long lifecycle

When support, maintenance and product evolution are required over many years, with full control of design and technology. Having the documentation and design rights allows switching manufacturers, updating components in the face of obsolescence and adapting the product to new requirements without depending on a single supplier of closed solutions.

Custom electronic projects at REIDITE Electronics

At REIDITE Electronics we develop fully custom electronic projects for industrial products, supporting our clients from concept definition through to series production. We work with companies in the industrial, aerospace and defence sectors that need reliable, well-documented solutions aligned with their technical and regulatory requirements.

Our approach combines advanced electronics engineering, embedded systems, FPGA and proprietary platforms (such as our System on Modules) to reduce technical risk and accelerate development, delivering robust, scalable solutions aligned with each sector’s requirements. If you have in mind a product that demands specific electronics —whether a control board, an embedded system or a communications module— we can help you take it from idea to production.

View our electronics engineering services or contact us to tell us about your project.