Difference between prototype, engineering model and qualification board in electronic products

During the development of electronic products, several design versions are created before reaching series production. Among the most common are the prototype, the engineering model and the qualification board. Each stage has a specific purpose, a different level of maturity and plays a key role in reducing technical, regulatory and production risks.

Understanding the differences between these stages helps plan development more effectively, avoid unnecessary iterations and accelerate the transition from concept to a reliable, certifiable industrial electronic product.

Index

- Electronic product development phases

- Electronic prototype

- Engineering model

- Qualification board

- Key differences summary

- End-to-end support at REIDITE Electronics

Electronic product development phases

Throughout the development process, the design evolves from exploratory versions to near-final implementations. This evolution typically includes three major milestones:

- Prototype: validation of the concept and basic architecture.

- Engineering model: design consolidation and extended functional validation.

- Qualification board: regulatory and reliability validation prior to production.

These phases are essential to ensure the final product meets all technical and regulatory requirements, minimizing risks and optimizing resources.

Electronic prototype

The prototype is the first functional version of the electronic design. Its main purpose is to validate the concept, the overall system architecture and basic hardware behaviour.

Prototypes are usually built in small quantities using flexible processes that allow rapid iteration. At this stage:

- The technical feasibility of the concept is validated.

- Interfaces, communications and functional blocks are tested.

- Full compliance with production or regulatory requirements is not yet mandatory.

The prototype allows for the early detection of conceptual errors, when the cost of change is still low. This is crucial to avoid unnecessary expenses in later stages of development.

Importance of the prototype in development

The prototype not only validates the concept but also provides a foundation for creating more advanced models. By identifying issues at this stage, adjustments can be made to improve the design's efficiency and functionality.

Additionally, the prototype serves as a communication tool between design and production teams, ensuring that all stakeholders understand the project's specifications and objectives.

Engineering model

The engineering model is a direct evolution of the prototype, with a much more stable and refined design. At this stage, the schematic and PCB have been reviewed, components are defined and design-for-manufacturing and reliability criteria have been applied.

The engineering model is used for:

- Extended electrical and functional validation.

- Integration with firmware and application software.

- Internal performance, power consumption and stability testing.

- Preparation for reliability and certification tests.

Although it is not yet the final version for production, the engineering model should already reflect the product's definitive architecture. This ensures that any necessary changes are identified and addressed before mass production.

Critical aspects of the engineering model

The engineering model is crucial for identifying potential issues related to mass production. It allows for detailed testing to ensure the design can be manufactured efficiently and cost-effectively.

Furthermore, this phase includes the integration of software and firmware, ensuring that all system components work cohesively and meet the expected quality standards.

Qualification board

The qualification board is a version of the design specifically intended for advanced validation. Its goal is to demonstrate compliance with regulatory, environmental and reliability requirements before industrialisation.

This version is typically used for:

- Electromagnetic compatibility (EMC) testing.

- Thermal and environmental testing.

- Electrical safety verification.

- Reliability and lifetime testing.

Qualification boards help identify and correct critical issues before series production, avoiding costly redesigns and delays. They are essential for industrial products with long lifecycles or strict regulatory requirements.

Testing and certifications in the qualification board

The tests conducted on the qualification board are fundamental to ensuring the product meets all applicable standards. This includes electromagnetic compatibility, electrical safety, and environmental resistance tests.

Additionally, the qualification board evaluates the product's reliability over time, ensuring it can withstand prolonged use conditions without significant failures.

Key differences summary

- Prototype: concept and basic functionality validation.

- Engineering model: stable design and extended testing.

- Qualification board: regulatory and reliability validation before production.

Each of these stages is essential for the successful development of electronic products. Understanding their differences and purposes helps optimize the development process and minimize risks.

End-to-end support at REIDITE Electronics

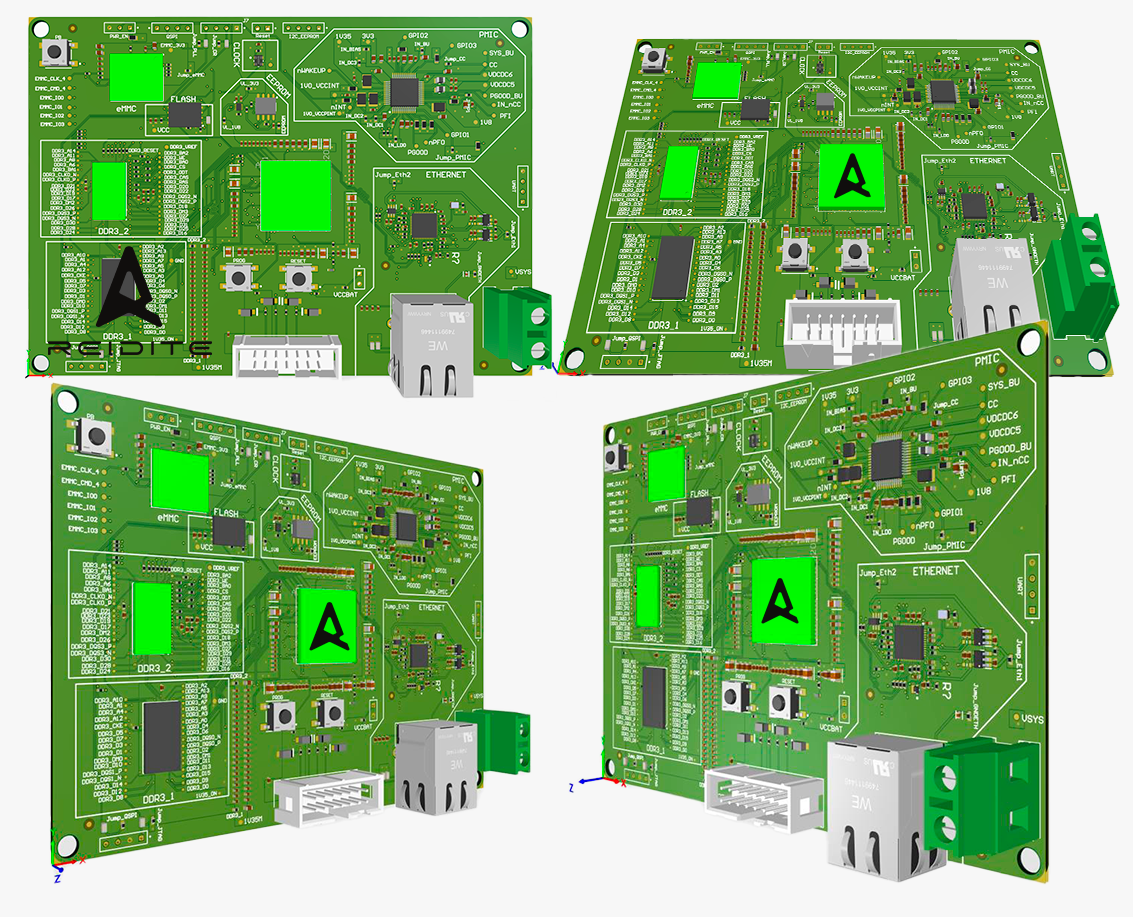

At REIDITE Electronics, we support our clients through all these stages of electronic development, from the first prototype to industrial production.

Our approach combines custom electronic design, rigorous validation and preparation for industrialisation, helping bring complex electronic products to market efficiently and with full technical control.

For more information on how we can assist in your product development, check out our custom electronic design services or contact us to discuss your project.