Advanced

Electronics Engineering

Custom electronic projects for industrial companies.

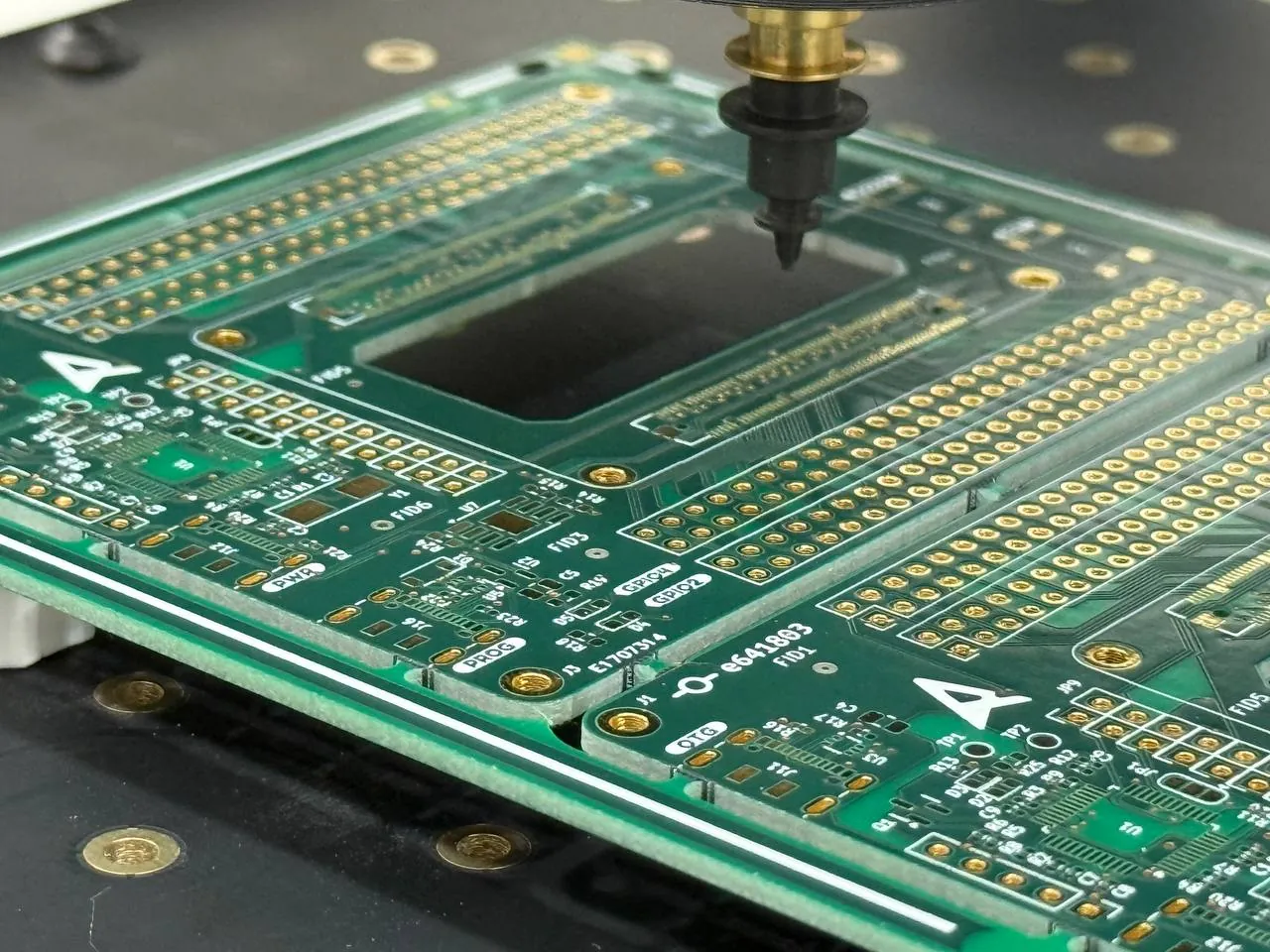

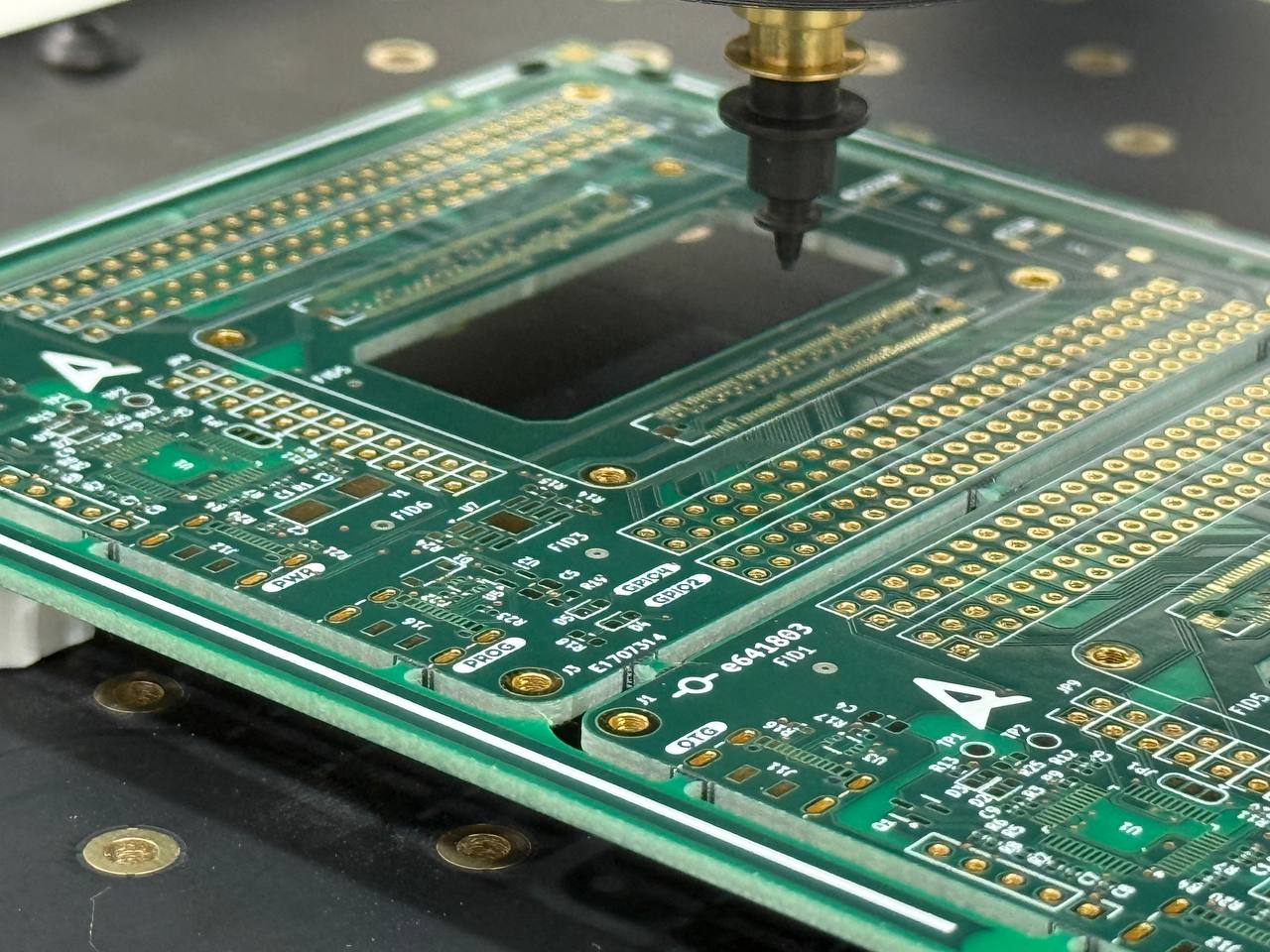

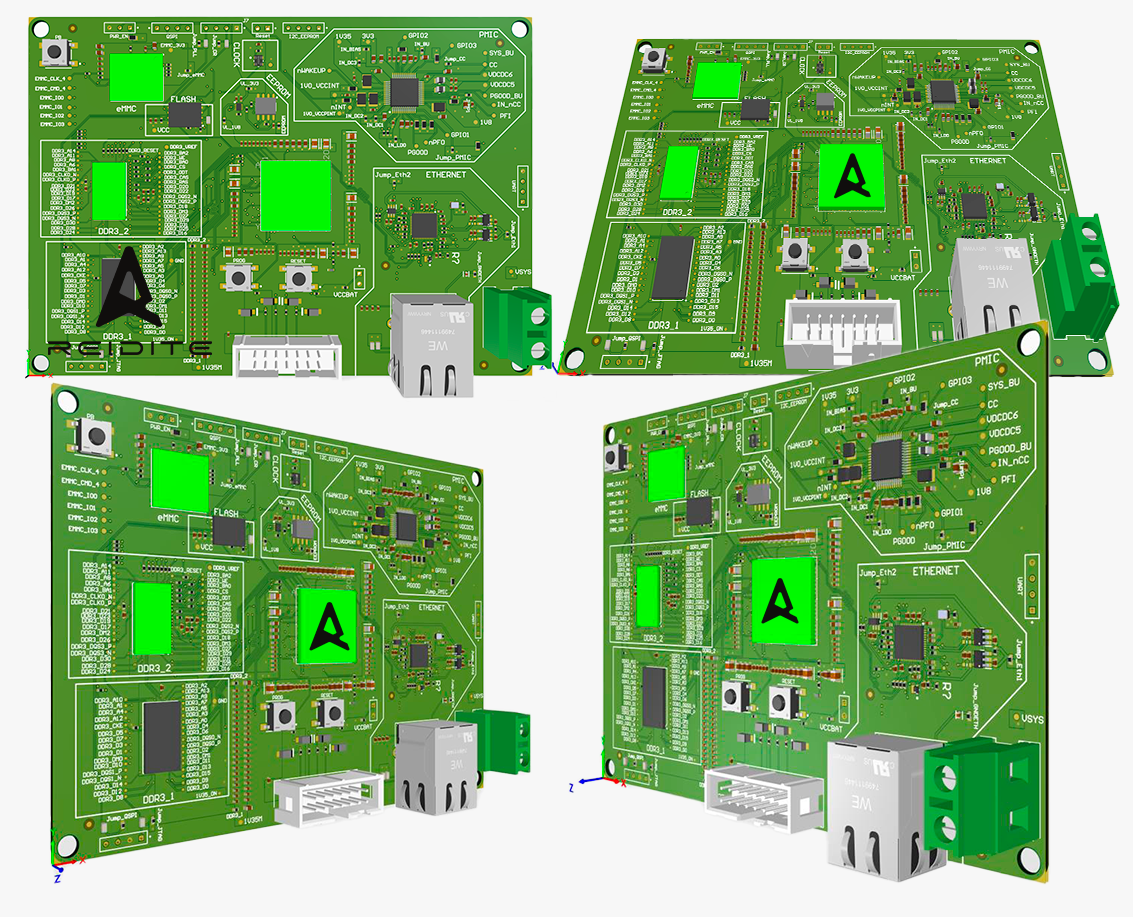

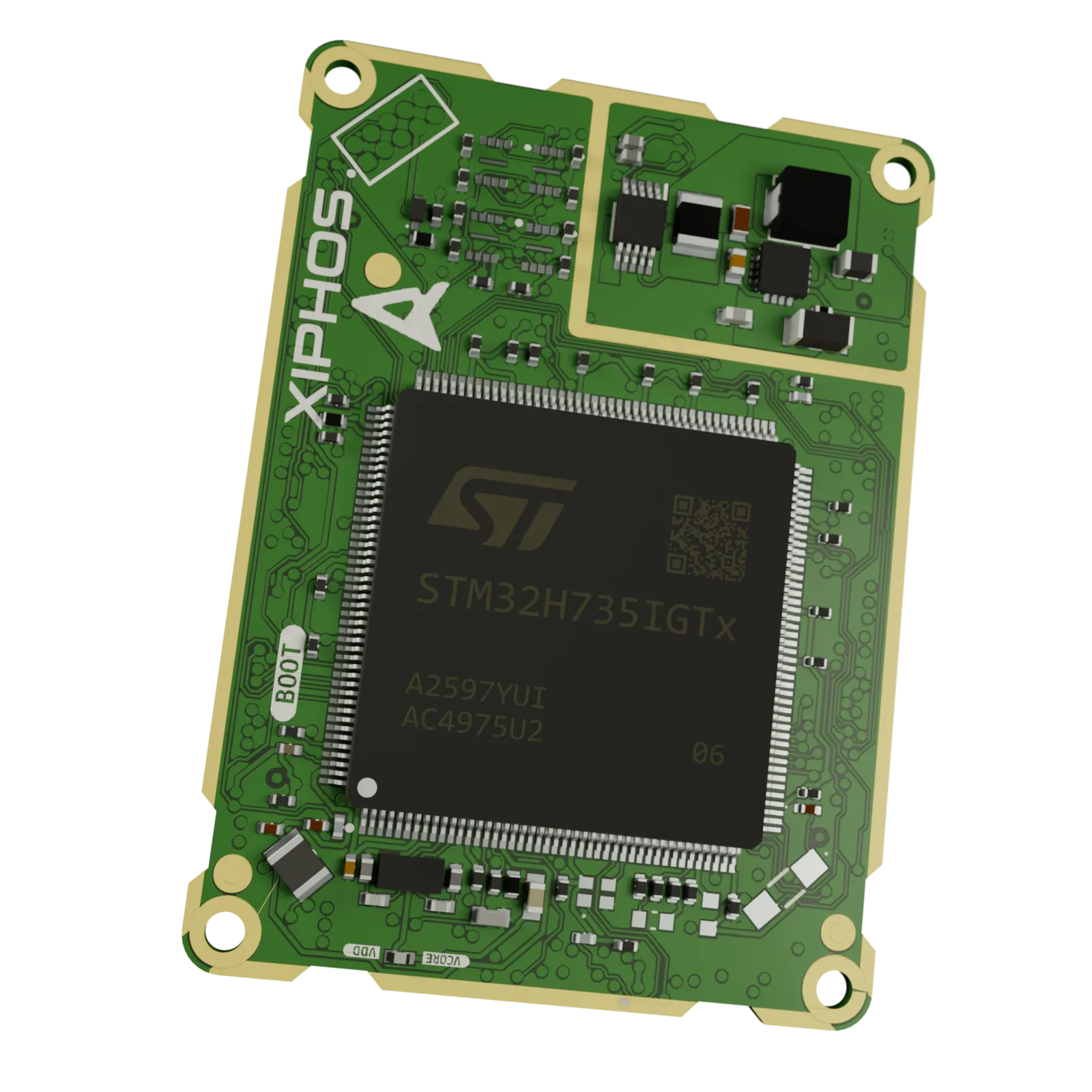

Full cycle: architecture, design and PCB, prototyping, validation, industrialisation and production.

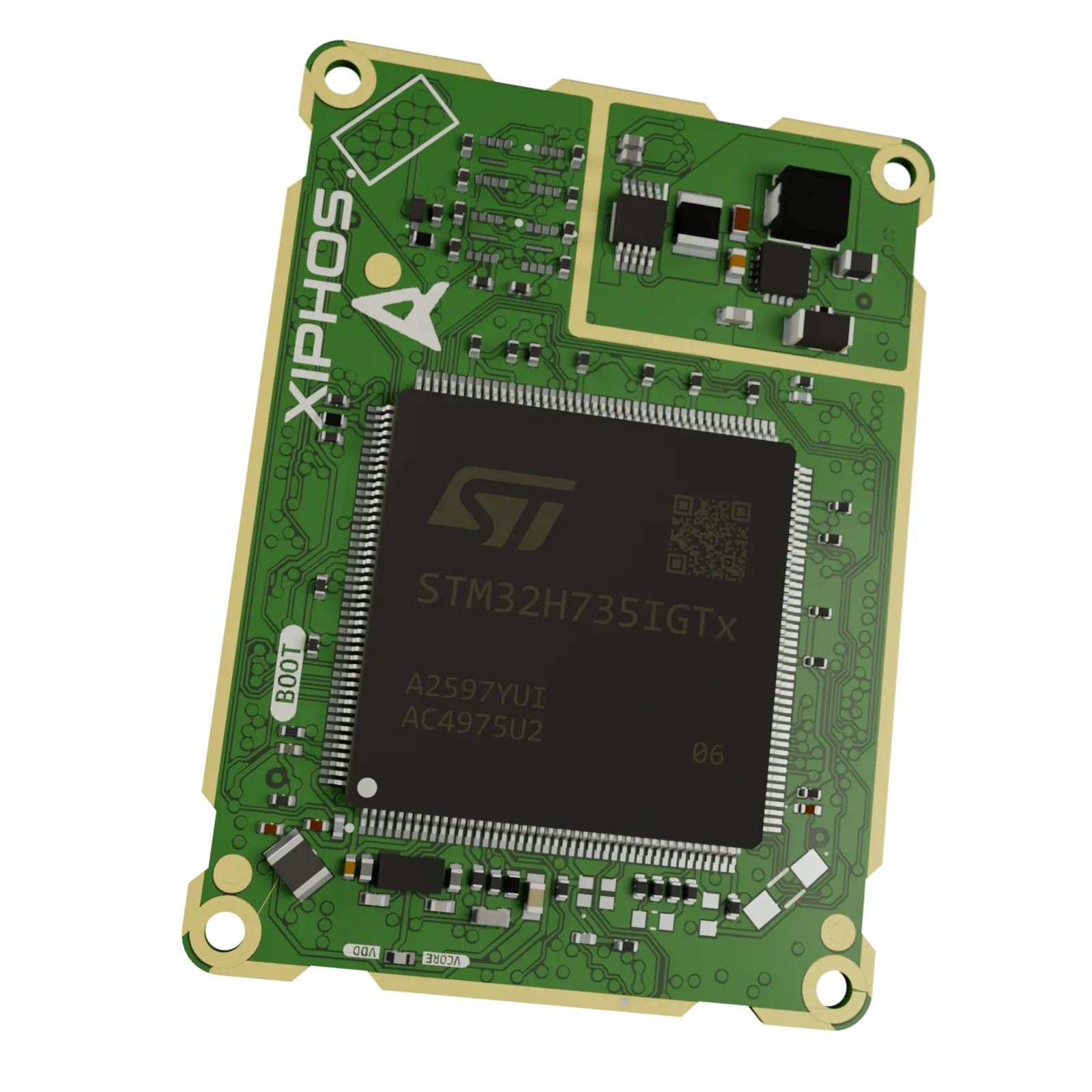

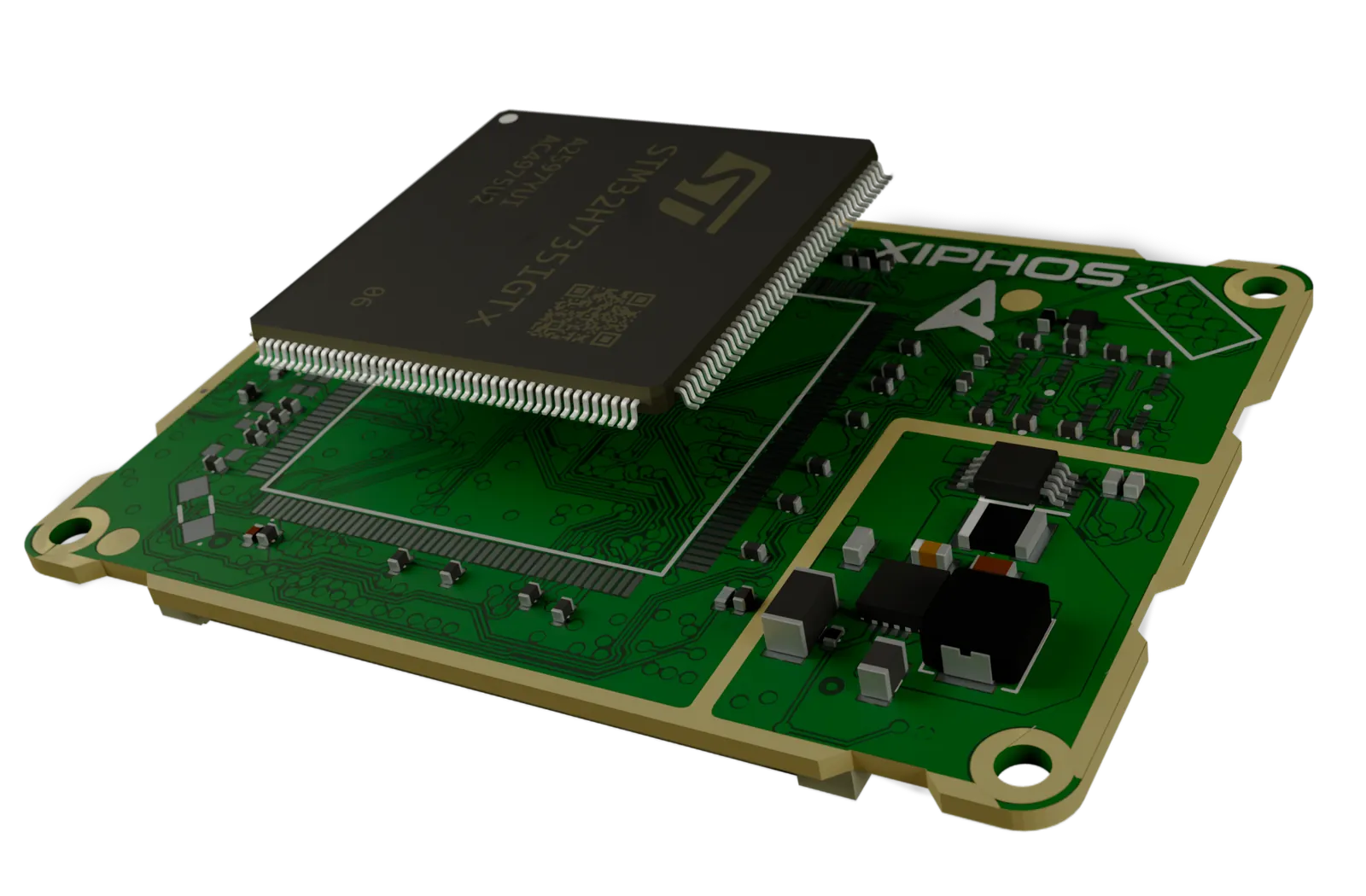

SoM, FPGA and RISC-V are the technological foundation to build your solution.